Six Sigma - Defect Metrics

Before we go ahead, let us define two terms:

● A Six Sigma defect is defined as anything outside of customer specifications.

● A Six Sigma opportunity is the total quantity of chances for a defect.

This chapter provides a list formulae normally used to measure different metrics related to Six Sigma defects.

Defects Per Unit - DPU

Total Number of Defects

DPU = ------------------------

Total number of Product Units

DPU = ------------------------

Total number of Product Units

The probability of getting 'r' defects in a sample having a given DPU rate can be predicted with the Poisson Distribution.

Total Opportunities - TO

TO = Total number of Product Units x Opportunities

Defects Per Opportunity - DPO

Total Number of Defects

DPO = ------------------------

Total Opportunity

DPO = ------------------------

Total Opportunity

Defects Per Million Opportunities - DPMO

DPMO = DPO x 1,000,000

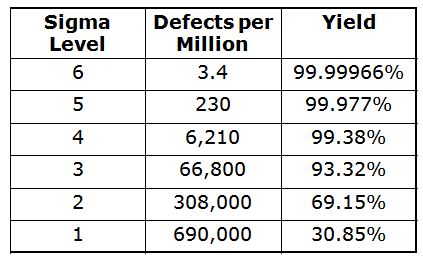

Defects Per Million Opportunities or DPMO can be then converted to sigma values using Yield to Sigma Conversion Table given in Six Sigma - Measure Phase.

According to the conversion table:

6 Sigma = 3.4 DPMO

How to find your Sigma Level

● Clearly define the customer's explicit requirements.

● Count the number of defects that occur.

● Determine the yield-percentage of items without defects.

● Use the conversion chart to determine DPMO and Sigma Level.

Simplified Sigma Conversion Table

If your yield is: Your DPMO is: Your Sigma is:

30.9% 690,000 1.0

62.9% 308,000 2.0

93.3 66,800 3.0

99.4 6,210 4.0

99.98 320 5.0

99.9997 3.4 6.0

30.9% 690,000 1.0

62.9% 308,000 2.0

93.3 66,800 3.0

99.4 6,210 4.0

99.98 320 5.0

99.9997 3.4 6.0

Six Sigma - Summary

We can summarize the following points:

● Six Sigma is a philosophy of quality improvement.

● Six Sigma is 3.4 defects in one million opportunities (DPMO).

● Components of Six Sigma are Customer, Process, and Employees.

● Six Sigma implementation requires the following roles:

○ Business Leader

○ Sponsor

○ Black Belt

○ Master Black Belt

○ Green Belt

● The generic cycle of Six Sigma includes the following phases: Define, Measure, Analyze, Improve, and Control.

● Six Sigma is dedicated to 'Customer focus'.

Comments

Post a Comment